ABOUT SALAMANDER TOOLS

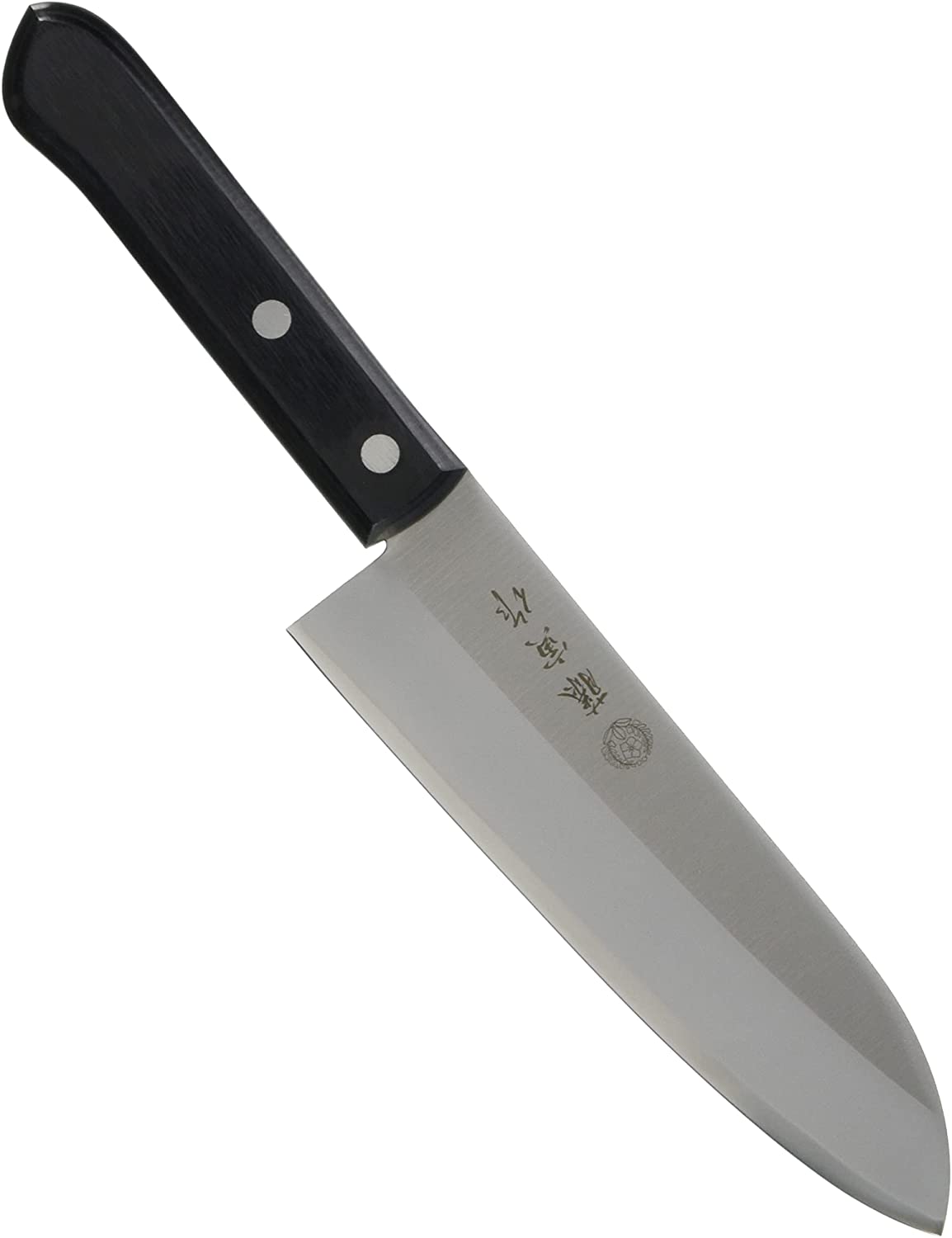

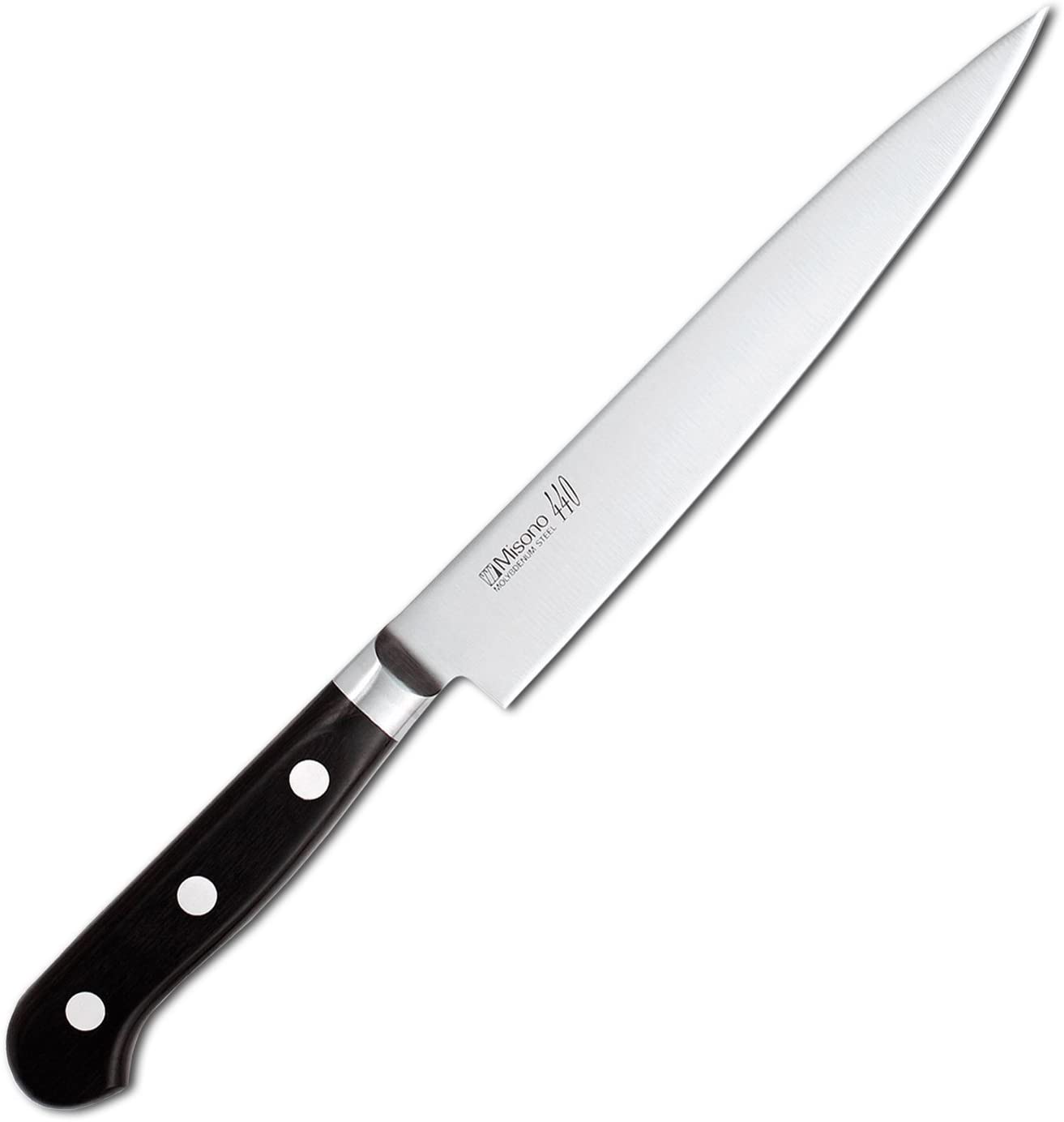

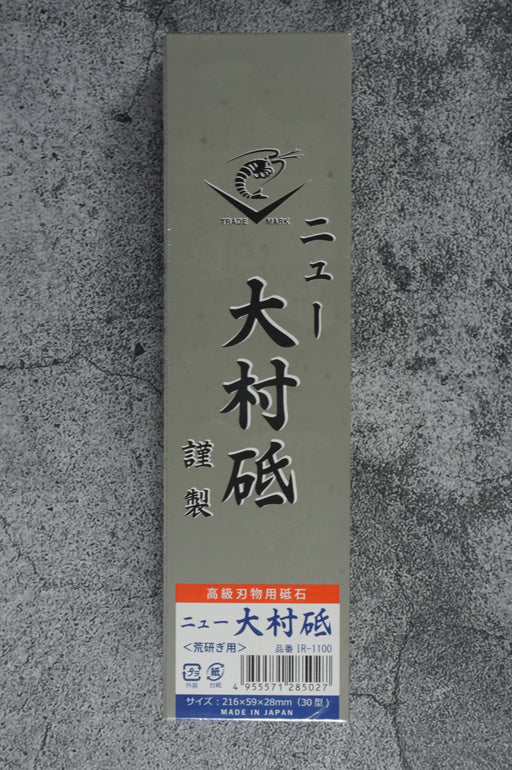

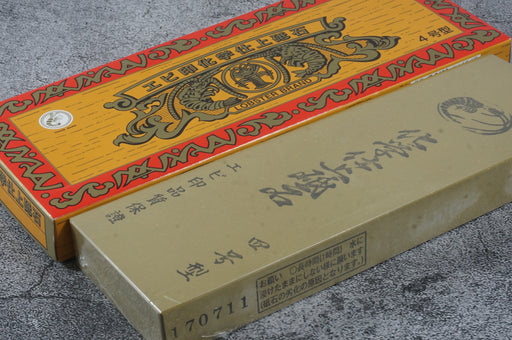

A majority of our products are made here in Japan.

Our products are often imitated, but can never be duplicated by other countries. Japanese craftsmanship is revered the world over. We can guarantee we will exceed your expectations and satisfaction with the quality of our products. Not to mention, we offer the best price's for products and shipping.

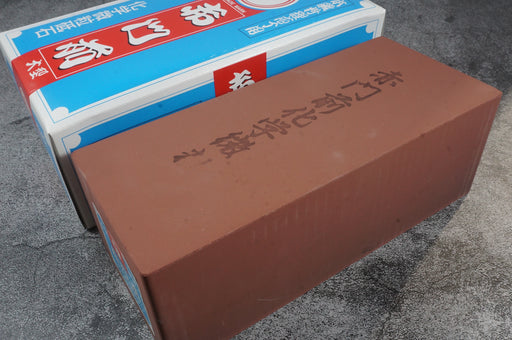

It's incredibly beneficial to our foreign customers because after they buy our Japanese made hand tools, they typically go years without having to do any special maintenance or repairs. Saving them, and you money in the long run.

We trust strongly that quality and durability are an essential cornerstone to our company and its products. Our many years in business is a true test to that.